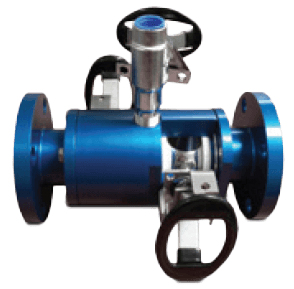

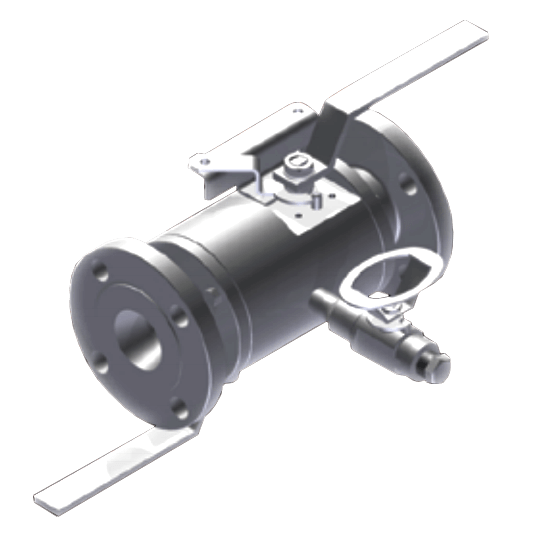

5500 Double Block & Bleed Ball Valve

Brand: CameronThe term Double Block-and-Bleed (DBB) has been an ongoing debate in the oil and gas industry, mainly because there are two credible sources that define the term differently. Basically, the difference is that API allows DBB to be one single valve with two unidirectional seats, while OSHA requires a DBB valve to be two individual valves in the same unit. In one compact design, the TBV Series 5500 double block-and-bleed (dbb) ball valve provides the two individual isolation valves required by OSHA. Features and Benefits:

- Instrument and pipeline valves

- 1/2" to 3" (15 mm to 80 mm)

- Pressure classes ASME 150 to 1,500

- Fire-safe design available according to API 607 6th edition

- Stem design per API 608

- Flange-to-flange or flange-to-pipe connections available

- Various sealing materials available, including PTFE-to-metal

- Standard materials of construction

- WCB carbon steel

- 316 stainless steel

- Duplex

Specifications

Brand

Applications

- Boiler Bridle Isolation

- Chemical Injection

- Emergency Shutdown (ESD)

- Gas Separation

- Pressure Equalization

- Pressure Instrument Connections

- Primary Isolation

- Sample Connections

- Venting

Approvals & Certifications

- API 607, 608

Ball Material

- 316 Stainless Steel

- Alloy 20 or Incoloy®

- Carbon Steel

- Duplex Stainless Steels - AL6XN

- Monel® 400

Enclosure, Body Material

- 316 Stainless Steel

- Alloy 20 or Incoloy®

- Carbon Steel

- Duplex Stainless Steel AL6XN

- Monel® 400

Flange Size - 1-1/2" (DN40)

- 1-1/2" (DN40) - 150# (ANSI)

- 1-1/2" (DN40) - 1500# (ANSI)

- 1-1/2" (DN40) - 300# (ANSI)

- 1-1/2" (DN40) - 600# (ANSI)

- 1-1/2" (DN40) - 900# (ANSI)

Flange Size - 1" (DN25)

- 1" (DN25) - 150# (ANSI)

- 1" (DN25) - 1500# (ANSI)

- 1" (DN25) - 300# (ANSI)

- 1" (DN25) - 600# (ANSI)

- 1" (DN25) - 900# (ANSI)

Flange Size - 1/2" (DN15)

- 1/2" (DN15) - 150# (ANSI)

- 1/2" (DN15) - 1500# (ANSI)

- 1/2" (DN15) - 300# (ANSI)

- 1/2" (DN15) - 600# (ANSI)

- 1/2" (DN15) - 900# (ANSI)

Flange Size - 2" (DN50)

- 2" (DN50) - 150# (ANSI)

- 2" (DN50) - 1500# (ANSI)

- 2" (DN50) - 300# (ANSI)

- 2" (DN50) - 600# (ANSI)

- 2" (DN50) - 900# (ANSI)

Flange Size - 3" (DN80)

- 3" (DN80) - 150# (ANSI)

- 3" (DN80) - 1500# (ANSI)

- 3" (DN80) - 300# (ANSI)

- 3" (DN80) - 600# (ANSI)

- 3" (DN80) - 900# (ANSI)

Flange Size - 3/4" (DN20)

- 3/4" (DN20) - 150# (ANSI)

- 3/4" (DN20) - 1500# (ANSI)

- 3/4" (DN20) - 300# (ANSI)

- 3/4" (DN20) - 600# (ANSI)

- 3/4" (DN20) - 900# (ANSI)

Nut & Bolt Material

- Bolt: Alloy 20 or Incoloy®

- Bolt: ASTM A193 B7

- Bolt: ASTM A193 B7M

- Bolt: ASTM A193 B8M

- Bolt: ASTM A193B8 CL2

- Bolt: ASTM A194 2H

- Bolt: ASTM A194 7M

- Bolt: ASTM A194 8M

- Bolt: ASTM A194 Gr8

- Bolt: ASTM A320 L7

- Bolt: ASTM A540 B21

- Bolt: Monel® K500

Operating Temperature

- 538° C (1000° F)

Port

- Reduced (Standard, Regular)

Seat / Seal Material

- Seal: Graphite

- Seal: TFE

- Seat: Arlon 1555 PEEK

- Seat: CTFE

- Seat: Glass-Filled Telfon

- Seat: Metal

- Seat: UHMWP

- Seat: Ultrafil

- Seat: Virgin Teflon

Stem Material

- 316 Stainless Steel

- Alloy 20 or Incoloy®

- Carbon Steel

- Duplex Stainless Steels - AL6XN

- Monel® 400

Tube Connection

- 1" Tube

- 1/2" Tube

- 1-1/2" Tube

- 2" Tube

- 3" Tube

- 3/4" Tube

Valve Size

- 1/2" to 3" (12.7 to 76.2) - Process Side & Instrument Side Valve Size

- 3/8" to 1" (9.5 to 25.4 mm) - Bleed Valve Size

Welded Connection

- 1" Butt Weld End

- 1" Socket Weld End Female

- 1" Socket Weld End Male

- 1/2" Butt Weld End

- 1/2" Socket Weld End Female

- 1/2" Socket Weld End Male

- 1-1/2" Butt Weld End

- 1-1/2" Socket Weld End Female

- 1-1/2" Socket Weld End Male

- 2" Butt Weld End

- 2" Socket Weld End Female

- 2" Socket Weld End Male

- 3" Butt Weld End

- 3" Socket Weld End Female

- 3" Socket Weld End Male

- 3/4" Butt Weld End

- 3/4" Socket Weld End Female

- 3/4" Socket Weld End Male