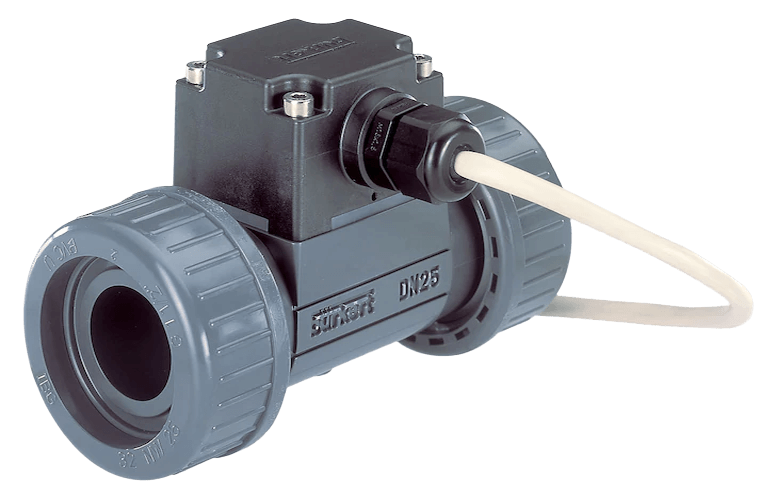

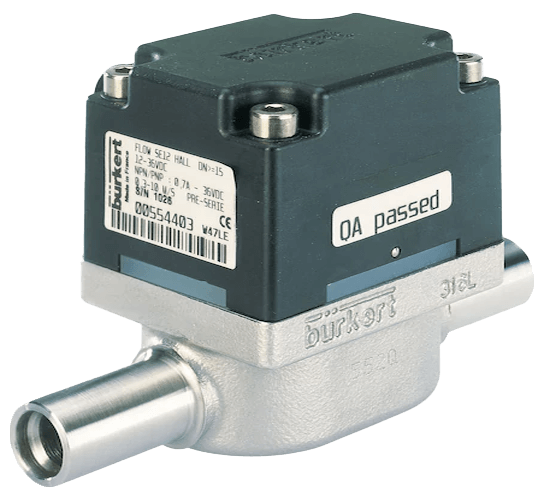

8012 Flowmeter with Paddle Wheel

Brand: Burkert Fluid Control SystemsThe paddle wheel flowmeter for continuous flow measurement is especially designed for use with neutral, slightly aggressive, solid free liquids in its magnetic measuring version and for use with liquids which let pass the infra-reds in its optic measuring version. The 8012 is made up of a fitting (S012) and an electronic module (SE12) which are connected together with screws.

The Burkert designed fitting system ensures simple installation into all pipes from DN06 to DN65. It can also be installed in fluid block systems. The 8012 produces a configurable frequency pulse signal, proportional to the flow rate, which can easily be transmitted and processed by a Burkert remote transmitter/ controller, or a configurable switch output or a 4-20 mA signal.

Features- Economic integration in pipe systems without any additional piping

- Optic or magnetic measuring principle

- Configurable output: 1 Analog 4-20 mA and/or 1 transistor output (frequency or switch)

- Outputs configurable (through interface on USB port with PC)

Specifications

Ambient Temperature Range

- Operating & Storage: -15° to 60° C (5° to 140° F)

Approvals & Certifications

- 3-Points Flow Calibration Certificate

- Certification of Conformity for the Surface Quality (DIN4762-DIN4768-ISO/4287/1)

- EN-ISO 10204, ISO 5167-1

- Inspection Certificate 3.1 (According to EN-ISO 10204)

- Test Report 2.2 (According to EN-ISO 10204)

Approvals & Certifications

- CE

- EU Directives

- FDA

- PED 2014/68/EU

Bearing Material

- Ceramics (AL₂O₃)

BSP Connection

- G 1" Female

- G 1/2" Female

- G 1/2" Male

- G 1/4" Male

- G 1-1/2" Female

- G 1-1/4" Female

- G 2" Female

- G 3/4" Female

- 1" BSPT Female

- 1/2" BSPT Female

- 1/2" BSPT Male

- 1-1/2" BSPT Female

- 1-1/4" BSPT Female

- 2" BSPT Female

- 3/4" BSPT Female

Cable Material

- 1 Meter Cable: PVC

Circuit Protection

- Short Circuit Protected for Transistor Output

Consumption

- Current: < 60 mA at 12 Vdc for Current Version, without Load

Current

- 4-20 mA, 3-Wire

Diameter

- Pipe: 1/4 to 2-1/2" (DN06 to DN65)

Electrical Connectors

- 1 Meter Cable Via Cable Gland

- 1.5 mm², Maximum

- Free Positionable 5-Pin M12 Male Fixed Connector

Electrical Protection

- Voltage Peak: Protected

Enclosure, Body Material

- PPS

Environmental Protection

- IP65

- IP67

Frequency

- Output: 0 to 250 Hz

Gland Material

- Polyamide (PA)

Humidity

- ≤ 80% Relative Humidity, Non-Condensing

Indication

- LED

Linearity

- ± 0.5% of Full Scale

Loop Impedance

- 1,125 ohms at 36 Vdc, Maximum

- 140 ohms at 12 Vdc, Maximum

- 650 ohms at 24 Vdc, Maximum

Materials of Construction

- M12 Fixed Connector: Polyamide (PA)

Measuring Error

- Measurement Deviation (Standard K-factor): ± 2.5% of the Measured Value

- Measurement Deviation (Teach-In): ± 1% of the Measured Value

Measuring Range

- 0.3 to 10 m/sec

NPT Connection

- 1" NPT Female

- 1/2" NPT Female

- 1/2" NPT Male

- 1/4" NPT Male

- 1-1/2" NPT Female

- 1-1/4" NPT Female

- 2" NPT Female

- 3/4" NPT Female

O-Ring Material

- EPDM

- FKM

Output

- Transistor (NPN): 0.2-36 Vdc

- Transistor: 700 mA - Maximum

Output Format

- Open Collector

Pipe Connection

- DN15 Pipe

- DN20 Pipe

- DN25 Pipe

- DN32 Pipe

- DN40 Pipe

- DN50 Pipe

- DN65 Pipe

Power Supply

- 12-36 Vdc, Filtered & Regulated

Pressure Range

- bar: 0 to 16

- kPa: 0 to 1,600

- psi: 0 to 232

Process Connection Material

- Metal

- Plastic

Process Temperature

- PP Fitting: 0° to 80° C (32° to 176° F)

- PVC Fitting: 0° to 60° C (32° to 140° F)

- Stainless Steel or Brass Fitting: -15° to 100° C (5° to 212° F) (If T° Ambient ≤ 45° C)

- Stainless Steel or Brass Fitting: -15° to 90° C (5° to 194° F) (If 45° C ≤ T° Ambient ≤ 60° C)

Repeatability

- ± 0.4% of the Measured Value

Reverse Polarity Protection

- Yes

Seat / Seal Material

- Seal: EPDM

- Seal: FKM

Switch Type

- Transistor (NPN & PNP)

Tri-Clamp Connection

- DN15 Tri-Clamp®

- DN20 Tri-Clamp®

- DN25 Tri-Clamp®

- DN32 Tri-Clamp®

- DN40 Tri-Clamp®

- DN50 Tri-Clamp®

- DN65 Tri-Clamp®

Viscosity

- 300 cSt, Maximum

Welded Connection

- DN 15 Weld End

- DN 20 Weld End

- DN 25 Weld End

- DN 32 Weld End

- DN 40 Weld End

- DN 50 Weld End

- DN 65 Weld End

Wetted Materials

- Axis: Ceramics (AL₂O₃)

- Fitting: 316L Stainless Steel, 1.4404

- Fitting: Brass

- Fitting: Polypropylene (PP)

- Fitting: PVC

- Paddle Wheel, Holder: PVDF