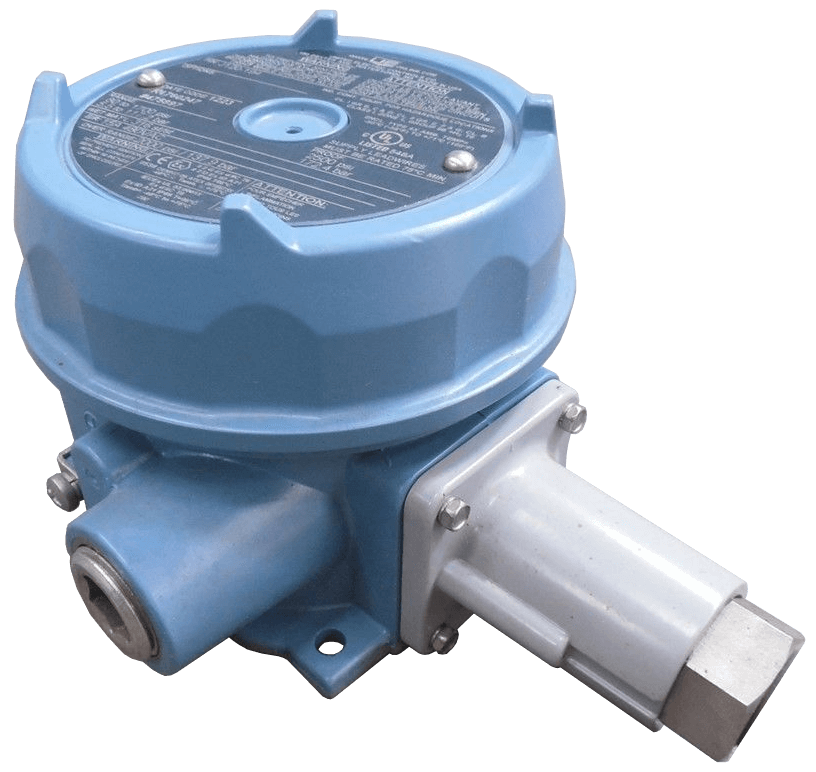

120 Series Type J120 Models 188 to 189/488 to 489 Pressure Switch

Brand: United Electric Controls Ltd.As safety requirements become more stringent, the determining factor in specifying an industrial pressure, differential pressure and/ or temperature switch rests upon that switch protecting equipment, processes and personnel. Meeting hazardous location requirements through worldwide approvals and certifications, UE's 120 Series is the choice where potentially explosive or highly corrosive atmospheres exist. The 120 Series offers a variety of pressure, vacuum, differential pressure and temperature ranges, as well as process connections, wetted materials and sensor types. With a common flexible platform, modelscan quickly be adapted at the factory for special requirements, such as ranges, process connections and electrical ratings. Typical industries using 120 Series switches include chemical, petrochemical, refinery and oil & gas production and transmission.

Features- Standard product approvals include cULus, ATEX & IECEx

- Many models compliant to NACE MR-0175

- Internal adjustment hex screw or external adjustment via calibrated dial(s) with tamper resistant cover

- Integral cover lock

- Wide variety of sensor materials

- Wide adjustable deadband models

- Heat tracing temperature models

Specifications

Adjustment Type

- Factory Set (Pre-Set)

Ambient Temperature Range

- -50° to 71° C ( -58° to 160° F)

Applications

- Chemicals

- Oil & Gas Production

- Petrochemical

- Refinery

- Transmission

Approvals & Certifications

- ISO 9001

Approvals & Certifications

- ATEX Directive (94/9/EC) II 2 G Ex D IIC T6 Gb II 2 D Ex Tb IIIC T85° C Db IP66 Tamb: -40° to 75° C (-40° to 167° F) UL International Demko A/S (N.B.# 0539) Certificate # Demko 09-ATEX-0815573X Rev. 2 EN 60079-0, 60079-1, 60079-31 II 1 G Ex Ia IIC T6 Ga

- CE

- CQST: CNEx15.2540X Ex D IIC T6 Gb Ex TD A21 T85° C IP66 Tamb. = -40° to 75° C (-40° to 167° F) GB3836.1, GB3836.2 & GB12476

- CRN

- CSA C22.2 No. 25 & 30 - File # E40857

- GOST-R 0Ex Ia IIC T6 Ga x Tamb: -50° to 60° C (-58° to 140° F) NANIO CCVE Certification Center RU C-US.ГБ05.B.01185 ГOCT P MЭК 60079-11, ГOCT P MЭК 60079-0-2011, ГOCT 31610.26, IEC 60079-26

- GOST-R 1Ex D IIC T6 Gb x Tamb: -50° to 80° C (-58° to 176° F)

- GOST-U 1ExdIICT6X Tamb: -56° to 85° C (-68.8° to 185° F) СВIДОЦТВО #720 by DVSTS VE (TCCExEE)

- IECEx Certified Ex D IIC T6 Gb Ex Tb IIIC T85° C Db IP66 Tamb. = -40° to 75° C (-40° to 167° F) IEC 60079-0, 60079-1, 60079-31 Certificate # IECEx UL 03.0001X

- INMETRO Ex D IIC T6 Gb Ex Tb IIIC T85° C Db IP66 -40° C ≤ Ta ≤ 75° C UL-BR 15.0179X ABNT NBR IEC 60079-0 ABNT NBR IEC 60079-1 ABNT NBR IEC 60079-31

- INMETRO Ex Ia IIC T6 Ga -50° C ≤ Ta ≤ 60° C UL-BR 15.0169X ABNT NBR IEC 60079-0 ABNT NBR IEC 60079-11 ABNT NBR IEC 60079-26

- KC

- KOSHA, Article 34 of Industrial Safety & Health Law Ex D IIC T6 -40° C < Tamb < 75° C, Certification# 10-AV4BO-0710

- Low Voltage Directive (LVD) 2006/95/EC

- PESO: CCEs Identification# P314108 / 1 EN 60079-0, 60079-1 Ex Ia IIC T6 Ga, CCEs Identification# P305465 / 1 EN 60079-0, 60079-11, 60079-26

- PED: 97/23/EC

- TS ML041200701AE7, ML041200701BY3, ML041200701C40, ML041200701D31

- UL (C,US) 50 & 1203: Class I, Division 1 & 2, Groups B, C, D, Class II, Division 1 & 2, Groups E, F, G, Class III, Class I, Zone 1, Group IIB + H2 T6

BSP Connection

- G 1/2" Male

Cover Material

- Gasketed Stainless Steel Tamper-Resistant Dial Cover

Deadband

- psi: 25 to 300 (kPa: 172.4 to 2,068, bar: 1.7 to 20.7)

Diaphragm Material

- 316L Stainless Steel

- Hastelloy® C-276

- Monel® 400

Electrical Connectors

- 3/4" NPT

- Terminal Block

Electrical Contacts

- Gold

- Normally Closed

- Normally Open

Electrical Rating

- 0.25 A at 250 Vdc Resistive

- 0.5 A at 125 Vdc

- 1 A at 125 Vac Resistive

- 1 A at 48 Vdc

- 11 A at 125/250 Vac Resistive

- 15 A at 125/250 Vac Resistive

- 15 A at 125/250/480 Vac Resistive

- 20 A at 125/250/480 Vac Resistive

- 3 A at 28 Vdc

- 5 A at 125/250 Vac Resistive

- 5 A at 30 Vdc

Enclosure Finish

- Epoxy Powder-Coated

Enclosure, Body Material

- Gasketed Die Cast Aluminum

Environmental Protection

- Flameproof

- Intrinsically Safe

- IP66

- Typical 4X

- Typical 7

- Typical 9

Mounting

- Pipe

- Surface

NACE & NIST

- NACE MR-0175

Name Plate, Tag Material

- Aluminum

- Stainless Steel

NPT Connection

- 1/2" NPT Female

- 1/2" NPT Male

- 1/4" NPT Male

O-Ring Material

- AFLAS®

- Ethylene Propylene (EPR)

- Kalrez®

- Viton GLT

Orifice Size

- 0.06" (1.52 mm) to Dampen Pulsations - Model 488 to 489

- 0.72" (18.28 mm) for Clean-Out Purposes - Model 188 to 189

Overpressure & Static Pressure Limits

- Over Range Pressure - psi: 2,000 to 4,000 (kPa: 13,790 to 27,580, bar: 137.9 to 275.5)

Process Connection Material

- 316 Stainless Steel

- Hastelloy® C-276

- Monel® 400

Proof Pressure

- psi: 7,000 (kPa: 48,260, bar: 482.6)

Repeatability

- Set Point Repeatability: ± 1/2% of Full Scale Range

Service

- Oxygen Service Cleaned in Accordance with ASTM G93, Verification Typical I, Tests 1 through 3

Set Point - Decreasing

- bar: 3.4 to 241.3

- kPa: 344.7 to 24,131

- psi: 50 to 3,500

Set Point - Increasing

- bar: 3.4 to 241.3

- kPa: 344.7 to 24,131

- psi: 50 to 3,500

Shock

- Set Point Repeats after 15 G, 10 millisecond Duration

Storage Temperature

- -54° to 71° C (-65° to 160° F)

Switch Type

- DPDT

- SPDT

System Pressure

- bar: 137.9 to 275.8

- kPa: 13,789 to 27,579

- psi: 2,000 to 4,000

Vibration

- Set Point Repeats after 2.5 G, 5 to 500 Hz