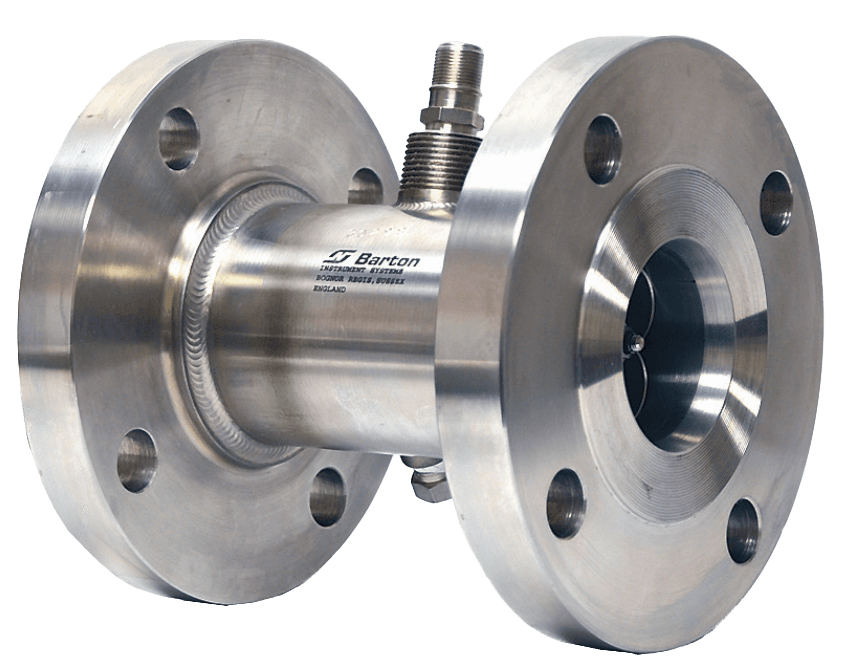

7400 Precision Gas Turbine Flow Meter

Brand: CameronBARTON model 7400 precision turbine flow meters are designed for gaservice in a wide range of industrial, commercial, pipeline and aerospace applications. Because the output from the pickup coil is digital, Model 7400 meters are an excellent match for electronic output devices no Analog to digital conversion is required. The rotor response is in milliseconds, providing precise metering in applications with rapidly changing flow patterns.

Specifications

Brand

Applications

- Aerospace Equipment

- Commercial

- Gas Transmission & Distribution

- Industrial Applications

- Metering of Gases from Oxygen to Ethylene for Natural Gas Production

- Pipelines

- Precise Metering

- Refineries & Petrochemical Plants

- Reverse Flow

- Wide

Approvals & Certifications

- ATEX Ex D IIC

- CE

- CEC

- CRN 0F0123.2C

- CSA: Hazardous Areas, Class I, Division I, Groups B, C, D, Class II, E,F,G: Class III, ANSI 12.27.01-2003 Single Seal Requirements

- NEC

- PED 97/23/CE

Bearing Material

- 440C Stainless Steel - Ball Bearings

BSP Connection

- 1" BSP Male

- 1-1/2" BSP Male

- 2" BSP Male

- 3/4" BSP Male

Density Range

- 0.08 to 4.5 Lbs/ft³(1.25 to 73 kg/m³) - Gas Density

- Flow Rate based on Air: 1 Lbs/ft³ (16 kg/m³)

Enclosure, Body Material

- 316 Stainless Steel

Environmental Protection

- Explosion-proof

- Flameproof

- Intrinsically Safe

- Water-Proof

- Weatherproof

Flange Material

- 316 Stainless Steel

Flange Size - 1-1/2" (DN40)

- 1-1/2" (DN40) - 1500#

- 1-1/2" (DN40) - 2500#

- 1-1/2" (DN40) - 600#

- 1-1/2" (DN40) - 900#

- 1-1/2" (DN40) - PN 100

- 1-1/2" (DN40) - PN 160

- 1-1/2" (DN40) - PN 250

- 1-1/2" (DN40) - PN 320

- 1-1/2" (DN40) - PN 64

Flange Size - 1" (DN25)

- 1" (DN25) - 1500#

- 1" (DN25) - 2500#

- 1" (DN25) - 600#

- 1" (DN25) - 900#

- 1" (DN25) - PN 100

- 1" (DN25) - PN 160

- 1" (DN25) - PN 250

- 1" (DN25) - PN 320

- 1" (DN25) - PN 64

Flange Size - 10" (DN250)

- 10" (DN250) - 1500#

- 10" (DN250) - 2500#

- 10" (DN250) - 600#

- 10" (DN250) - 900#

- 10" (DN250) - PN 100

- 10" (DN250) - PN 160

- 10" (DN250) - PN 250

- 10" (DN250) - PN 320

- 10" (DN250) - PN 64

Flange Size - 12" (DN300)

- 12" (DN300) - 1500#

- 12" (DN300) - 2500#

- 12" (DN300) - 600#

- 12" (DN300) - 900#

- 12" (DN300) - PN 100

- 12" (DN300) - PN 160

- 12" (DN300) - PN 250

- 12" (DN300) - PN 320

- 12" (DN300) - PN 64

Flange Size - 2" (DN50)

- 2" (DN50) - 1500#

- 2" (DN50) - 2500#

- 2" (DN50) - 600#

- 2" (DN50) - 900#

- 2" (DN50) - PN 100

- 2" (DN50) - PN 160

- 2" (DN50) - PN 250

- 2" (DN50) - PN 320

- 2" (DN50) - PN 64

Flange Size - 3" (DN80)

- 3" (DN80) - 1500#

- 3" (DN80) - 2500#

- 3" (DN80) - 600#

- 3" (DN80) - 900#

- 3" (DN80) - PN 100

- 3" (DN80) - PN 160

- 3" (DN80) - PN 250

- 3" (DN80) - PN 320

- 3" (DN80) - PN 64

Flange Size - 3/4" (DN20)

- 3/4" (DN20) - 1500#

- 3/4" (DN20) - 2500#

- 3/4" (DN20) - 600#

- 3/4" (DN20) - 900#

- 3/4" (DN20) - PN 100

- 3/4" (DN20) - PN 160

- 3/4" (DN20) - PN 250

- 3/4" (DN20) - PN 320

- 3/4" (DN20) - PN 64

Flange Size - 4" (DN100)

- 4" (DN100) - 1500#

- 4" (DN100) - 2500#

- 4" (DN100) - 600#

- 4" (DN100) - 900#

- 4" (DN100) - PN 100

- 4" (DN100) - PN 160

- 4" (DN100) - PN 250

- 4" (DN100) - PN 320

- 4" (DN100) - PN 64

Flange Size - 6" (DN150)

- 6" (DN150) - 1500#

- 6" (DN150) - 2500#

- 6" (DN150) - 600#

- 6" (DN150) - 900#

- 6" (DN150) - PN 100

- 6" (DN150) - PN 250

- 6" (DN150) - PN 320

- 6" (DN150) - PN 64

- 6" (DN150) - PN160

Flange Size - 8" (DN200)

- 8" (DN200) - 1500#

- 8" (DN200) - 2500#

- 8" (DN200) - 600#

- 8" (DN200) - 900#

- 8" (DN200) - PN 100

- 8" (DN200) - PN 160

- 8" (DN200) - PN 250

- 8" (DN200) - PN 320

- 8" (DN200) - PN 64

Frequency

- 450 to 3540 Hz

Linearity

- K-Factor: ± 1% of Reading

Materials of Construction

- 430 Stainless Steel - Rotor Blades

Media

- Gas

- Water

Mounting

- Direct Mounting to the Turbine

- Remote Mounting

Mounting Position

- Meter Can be Installed in Any Orientation

NPT Connection

- 1" NPT Male

- 1-1/2" NPT Male

- 2" NPT Male

- 3/4" NPT Male

Output

- 0.2-5 V Rms on 12” (300 mm)

- 20-500 mV Rms on 3/4” (20 mm)

Output Format

- Sine Wave

Pressure Range

- psi: 2,650 to 5,000 (MPa: 18.3 to 34.5, bar: 183 to 345)

Process Temperature

- -29° to 150° C (-20° to 302° F)

Repeatability

- ± 0.02%

- ± 0.2% of Flow Rate Repeatability

Rotation

- Bi-Directional

Size

- 3/4" to 12" (19 to 304.8 mm) - Body

Turndown

- 10:1