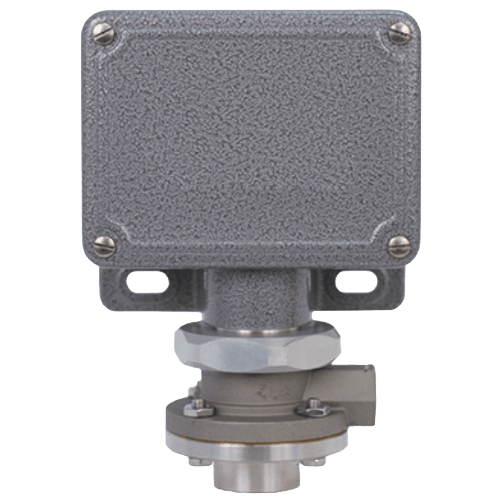

101/121 Differential Pressure Switch

Brand: Cameron101/121 differential pressure switches are rugged, field-mounted instruments that incorporate a flexible modular design providing cost effective sensing solutions. The two-piece piston design allows for complete differential pressure reversal without damage. Process pressure is sensed by a diaphragm-piston combination. Hi-side system pressure acts on the piston to product force Fh. It is counteracted by the adjustable range spring force Fs and Lo-side system pressure acting on the backside of the piston to produce force Fl. The resultant force Fd acts on the piston and overcomes the force of the adjustable range spring [Fd= Fh – (Fl + Fs)] and moves a shaft that actuates (deactuates) an electrical switching element.

Specifications

Brand

Ambient Temperature Range

- -54° to 204° C (-65° to 400° F)

Applications

- Air

- Fluid Power

- Low to High Differential Pressure

- Oil & Non-Corrosive Process

- Process Applications

- Water

Approvals & Certifications

- ATEX: EEx D IIC T6/T5, Ex Ia IIC T6 to T4 Gb

- CSA: for Hazardous Locations Class I, Grade A, B, C, D, Class II, Groups E, F, G, Divisions 1 & 2

- SAA

- UL: for Hazardous Locations Class I, Groups B, C, D, Class II, Groups E, F, G, Divisions 1 & 2

Approvals & Certifications

- Calibration

- Compliance/Conformance

- Dielectric Test

- Hydrostatic Pressure Test

- Inspection Report

- Insulation Resistance

- Typical Material of Wetted Parts

BSP Connection

- 1/4" BSP Female

Cover Material

- Aluminum

Deadband

- psi: 0 to 20 (kPa: 0 to 138, bar: 0 to 1.38)

Diaphragm Material

- 316 Stainless Steel

- Hastelloy® B

- Teflon-Coated Polyimide

- Viton

Electrical Connectors

- 1/2" NPT Male

- 3/4" NPT Female

- Exposed Contacts

- M20 x 1.5

Electrical Contacts

- Normally Closed

- Normally Open

Electrical Rating

- 0.25-7 A at 30-250 Vdc - Resistive

- 1-15 A at 125-250 Vac

Enclosure, Body Material

- 316 Stainless Steel

- Aluminum

- Carbon Steel

- Cast Iron

- Copper-free Aluminum

Environmental Protection

- Explosion-proof

- Hazardous Area

- IP65

- NEMA 1

- NEMA 4

- NEMA 4X

- Non-Hazardous Area

Gasket Material

- Cover: Heavy Duty with Viton - Gasket Material

- Neoprene Cover Gasket

Maximum System Pressure

- psi: 1,000 (kPa: 6,895, bar: 69) - 121 Model

- psi: 500 (kPa: 3,447, bar: 34.47) - 101 Model

NPT Connection

- 1/4" NPT Female

O-Ring Material

- Buna-N

- Viton

Pressure Range

- psid: 0 to 500 (kPa: 0 to 3,447, bar: 0 to 34.47)

Process Connection Material

- 316 Stainless Steel

- CF-8M Cast Alloy

Set Point - Decreasing

- bar: 0 to 34.5

- kPa: 0 to 3,447

- psi: 0 to 500

Set Point - Increasing

- bar: 0 to 34.5

- kPa: 0 to 3,447

- psi: 0 to 500

Switch Type

- DPDT

- SPDT

System Pressure

- bar: 0 to 68.95

- kPa: 0 to 6895

- psi: 0 to 1000

Temperature Range

- 0° to 204° C (32° to 400° F) - Viton (O-Ring Material)

- -34° to 204° C (-30° to 400° F) - TCP-Teflon Coated Polyimide (O-Ring & Diaphragm Material)

- -34° to 93° C (-32° to 200° F) - Buna-N (O-Ring Material)